Now Reading: AI in Manufacturing: The Rise of Smart Factories

-

01

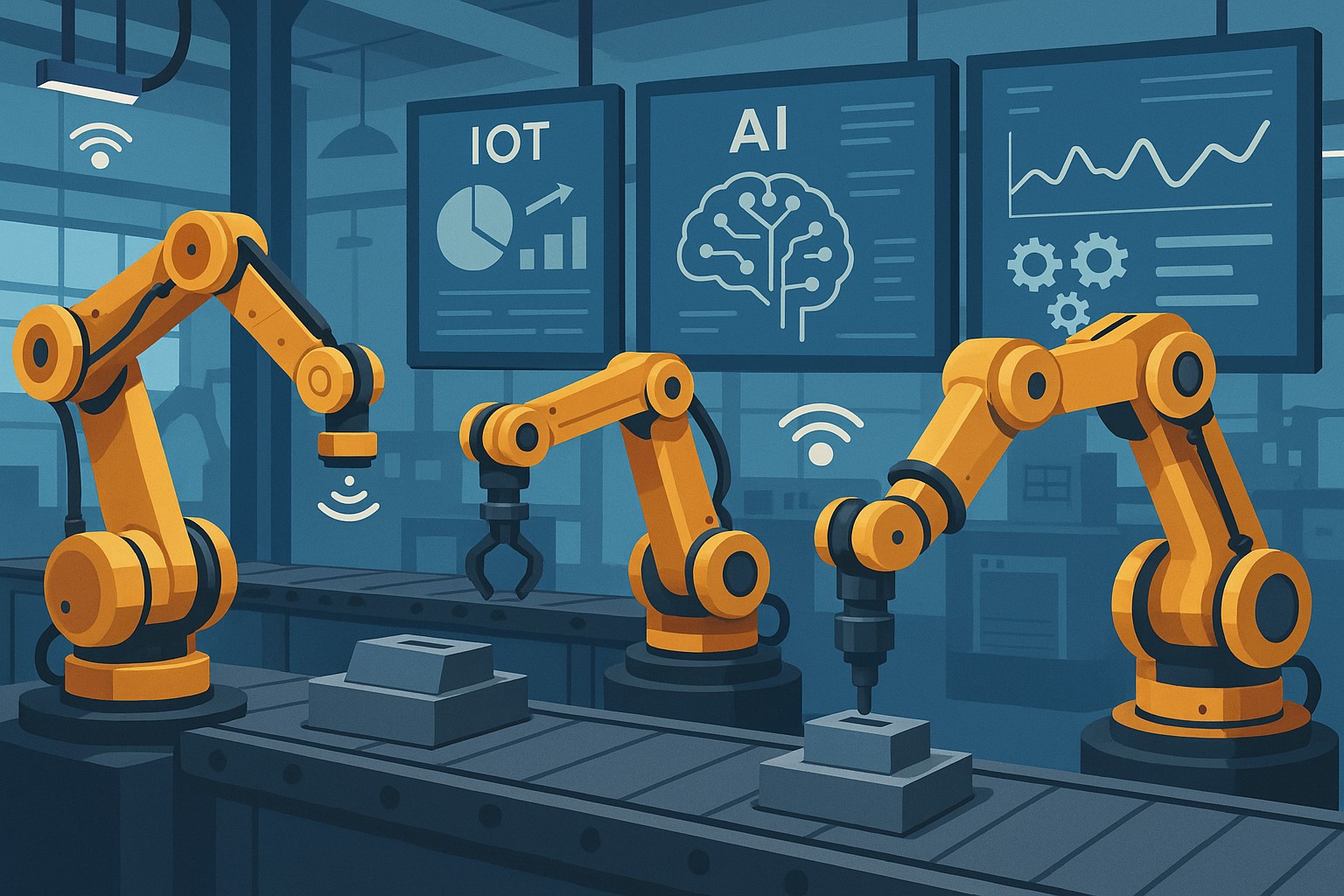

AI in Manufacturing: The Rise of Smart Factories

AI in Manufacturing: The Rise of Smart Factories

Overview of AI in Manufacturing

Artificial intelligence is reshaping how plants operate, shifting from static, manual control toward adaptive systems that learn from data and improve over time. In modern manufacturing, AI weaves together sensor streams, machine data, and enterprise systems to create a living network of assets, processes, and people. The result is a factory floor that can respond to demand, quality signals, and equipment health in near real time, without sacrificing efficiency or consistency.

As companies pursue higher productivity, AI-enabled manufacturing is increasingly synonymous with smart factories—facilities that use data-driven insights to optimize performance across the entire value chain. By enabling predictive maintenance, autonomous operations, and AI-driven quality control, these factories deliver greater flexibility, shorter changeover times, and more resilient production. This trend is especially pronounced in industries with high variability in demand or stringent quality requirements, where even small gains in uptime or yield compound into meaningful competitive advantages. SAP smart manufacturing and similar platforms are helping organizations standardize data models and workflows to unlock these capabilities at scale.

Core technologies powering smart factories

At the heart of the smart factory are technologies that turn raw data into actionable intelligence. Machine learning and predictive analytics scan historical and real-time data to forecast outcomes, detect anomalies, and prescribe steps to prevent problems before they escalate. Computer vision, often deployed on cameras and sensors, interprets visual signals to identify defects, verify assembly steps, and guide robotic systems with high precision. Digital twins simulate production lines and processes, enabling rapid experimentation and optimization without disrupting actual manufacturing.

Complementing these technologies are edge computing and real-time decisioning, which bring intelligence closer to the source of data to reduce latency and reliance on centralized data centers. This fusion of AI, sensing, and simulation allows factories to react quickly to changing conditions, while maintaining strict controls over quality and safety. Together, these core technologies enable smarter scheduling, adaptive control, and autonomous coordination among machines, robots, and human workers. The result is a more responsive, efficient, and data-driven production environment.

- Machine learning and predictive analytics

- Computer vision and sensory data fusion

- Digital twins and simulation

- Edge computing and real-time decisioning

- Reinforcement learning and autonomous control

Predictive maintenance and asset health

Predictive maintenance uses AI to anticipate when a machine will fail or degrade, enabling service before a disruption occurs. By combining sensor data, maintenance history, and operating context, models estimate remaining useful life, optimize maintenance windows, and reduce unplanned downtime. This shift from reactive to proactive maintenance translates into longer equipment life, steadier production, and lower spare-parts costs, all of which directly impact the bottom line.

Implementing predictive maintenance requires a disciplined approach to data and process integration. Engineers map critical assets and failure modes, establish data pipelines from IIoT sensors to a centralized analytics platform, and validate models against historical outage events. The optimization process also connects with maintenance workflows, ERP systems, and parts inventories, ensuring recommendations translate into work orders and timely interventions. Over time, models are retrained with new data to improve accuracy and adapt to evolving operating conditions.

- Map critical assets and failure modes

- Instrument data collection and ensure data quality

- Develop and validate predictive models

- Deploy models in edge or cloud environments with monitoring

- Integrate with maintenance workflows and ERP systems

- Continuously monitor, retrain, and refine the system

Robotics, automation, and human-robot collaboration

Robotics powered by AI automate repetitive, dangerous, or precision-critical tasks while preserving the flexibility to reprogram for new products. Collaborative robots, or cobots, work alongside humans, handling pick-and-place, assembly, and packaging tasks with high repeatability and safety. AI enhances robot perception, motion planning, and task optimization, enabling smoother handoffs between machines and operators and reducing the time required to introduce new lines or product variants.

To maximize the value of robotics, manufacturers blend automation with human expertise. AI-driven systems provide operators with real-time guidance, quality insights, and task suggestions, enabling workers to focus on higher-value activities. This collaboration not only improves throughput but also supports safer, more engaging work environments. Driving success requires careful change management, ergonomic considerations, and ongoing training to align capabilities with evolving production goals.

AI-driven quality control and process optimization

Quality control benefits from AI by moving inspection from static sampling to continuous, data-driven monitoring. Computer vision and sensor analytics detect defects and deviations at multiple stages, triggering immediate adjustments or process changes. AI can also optimize process parameters across machines and lines, reducing scrap, improving consistency, and shortening cycles without sacrificing accuracy or compliance.

Beyond defect detection, AI-enabled optimization closes the loop between design, manufacturing, and quality feedback. Process engineers can simulate parameter changes in a digital twin, forecast outcomes, and implement configurations that yield the best balance of speed, cost, and quality. The resulting process visibility helps manufacturers meet tighter specifications and stricter regulatory requirements while maintaining throughput and traceability across large-scale operations.

Data, integration, and platform considerations

Successful AI in manufacturing hinges on robust data foundations. Enterprises must harmonize data from MES, ERP, PLM, equipment PLCs, and third-party systems, ensuring consistent identifiers, timestamps, and data quality. A well-governed data platform supports data lineage, versioning, and access controls, enabling trusted analytics across production networks. In practice, this means standardized data models, centralized cataloging, and clear ownership for data products used by AI applications.

Platform choices influence deployment patterns, particularly the balance between cloud and edge processing. Edge-first architectures reduce latency and support offline capabilities on the plant floor, while cloud-based analytics enable more extensive model training and cross-site benchmarking. A scalable, interoperable architecture is essential, with openness to integrate SAP smart manufacturing, other ERP suites, and best-of-breed analytics tools to accelerate value realization and governance across the enterprise.

Security, governance, and risk management

AI-powered manufacturing introduces new cybersecurity and governance challenges. Protecting intellectual property, sensor data, and model weights requires layered security, continuous monitoring, and access controls aligned with industry regulations. Additionally, model risk management is essential to ensure that AI systems behave predictably, particularly when they influence maintenance decisions, safety-critical operations, or compliance-related processes.

Governance extends to data quality, auditing, and change control. Organizations should implement clear policies for model validation, versioning, and rollback, as well as documentation of assumptions and limitations. Regular risk assessments, incident response planning, and ongoing security testing help maintain confidence in AI-enabled production while supporting responsible innovation and long-term resilience.

Change management and workforce implications

Adopting AI in manufacturing changes how people work and how teams collaborate across engineering, operations, and maintenance. Successful programs prioritize reskilling and cross-functional training that empower operators to interpret AI recommendations, validate automated actions, and contribute to continuous improvement. In many cases, new roles emerge—data stewards, AI copilots for operators, and model engineers—requiring thoughtful organizational design and incentive structures.

Culture matters as much as technology. Leaders must communicate clear value propositions, establish governance for AI initiatives, and create feedback loops that translate shop-floor observations into model refinements. When people see tangible benefits—fewer outages, faster changeovers, and higher quality—the adoption curve accelerates and becomes self-sustaining across the enterprise.

Roadmap to an AI-enabled smart factory

A practical roadmap starts with a value-driven assessment that identifies where AI can deliver the largest impact, such as reducing downtime or improving yield. Next comes building a solid data foundation: cataloging assets, integrating data streams, and ensuring reliable data quality. Early pilots should target well-defined use cases with measurable metrics, followed by iterative scaling to additional lines, products, and sites. Governance, change management, and security are ongoing requirements throughout the journey.

As manufacturers mature, the focus shifts to scalable platforms, governance of AI assets, and continuous optimization. Cross-functional teams collaborate to refine models, expand data coverage, and standardize workflows so that AI-enabled insights become an everyday part of decision-making. Platforms like sap smart manufacturing can help accelerate this transition by providing common data models, pre-built components, and governance frameworks that align with broader digital transformation goals.

Benefits and business outcomes

AI-powered manufacturing delivers measurable improvements across uptime, quality, efficiency, and responsiveness. By aligning data-driven insights with real-world operations, plants can operate closer to design targets while accommodating variability in demand and supply. The cumulative effect of these gains is often a lower cost of production per unit, higher customer satisfaction, and a more agile competitive posture in markets that reward speed and precision.

In addition to operational gains, AI enables more resilient and sustainable manufacturing. Optimized energy use, reduced waste, and smarter maintenance schedules translate into lower environmental impact and better compliance with evolving regulatory expectations. The combination of stronger performance metrics and sustainable practices often enhances investor confidence and positions the business for long-term growth.

- Increased asset uptime and reduced unplanned downtime

- Improved product quality and reduced scrap

- Lower operational costs through efficiency gains

- Greater flexibility to ramp production for new products

- Faster time-to-market with safer, more reliable processes

- Improved visibility and traceability across the value chain

FAQ

What is AI in manufacturing?

AI in manufacturing refers to the application of artificial intelligence techniques to analyze data from machines, sensors, and processes to optimize performance, predict failures, and automate decisions. It spans predictive maintenance, quality control, robotics, and process optimization, all aimed at increasing uptime, yield, and efficiency.

How does AI improve predictive maintenance?

AI improves predictive maintenance by combining historical failure data with real-time sensor readings to forecast when a component will fail or degrade. This enables planned maintenance before an outage, reducing downtime, extending asset life, and lowering spare-part costs, while aligning maintenance with production schedules.

What are common challenges when implementing AI in manufacturing?

Common challenges include data quality and integration, aligning AI initiatives with business goals, change management to foster adoption, and ensuring security and governance. Successful programs require a clear data strategy, cross-functional collaboration, and ongoing monitoring to sustain value over time.

How do you assess readiness for SAP smart manufacturing?

Assess readiness by mapping current data sources, interfaces, and governance practices; evaluate the alignment of IT and OT teams; and identify high-impact use cases with clear metrics. A phased plan with pilot projects and measurable ROI helps determine how SAP smart manufacturing can accelerate maturity and scale across sites.

What is the typical ROI timeframe for smart factory AI projects?

ROI timelines vary by use case and industry, but many organizations target a 12–24 month horizon for initial pilots that demonstrate tangible improvements in uptime, quality, or throughput. Long-term value typically accrues as data quality improves, processes become standardized, and scaling across lines reduces incremental costs.

How can small and medium-sized enterprises start with AI in manufacturing?

SMEs can begin with a focused, high-impact use case, such as digital quality inspection or predictive maintenance on a critical asset. Building a lightweight data foundation, leveraging cloud-based analytics, and partnering with technology providers can accelerate value while keeping risk and cost manageable for smaller operations.